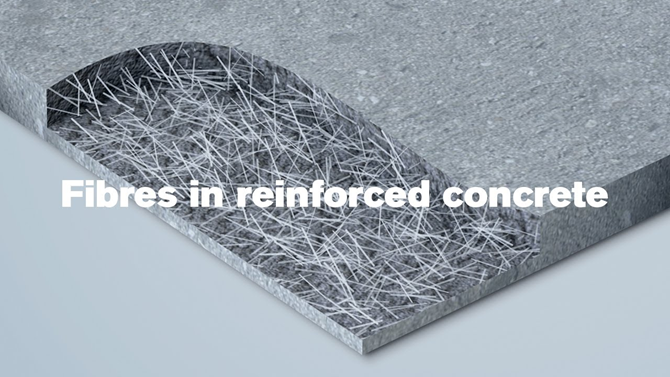

Steel Fiber Reinforced Concrete (SFRC) is a modern composite material. By adding fibers to the concrete, a load bearing capacity similar to traditionally reinforced concrete is obtained. Compared to traditional mesh/ bar solutions, SFRC provides better crack control.

For an increasing number of applications, the load bearing resistance of SFRC allows the partial or complete substitution of traditional reinforcement. The use of SFRC technology brings major time and cost saving. All the fibers are low carbon, cold drawn, high tensile steel wire produced using the most modern equipments. These fibers are ASTM compliant and designed to meet all performance parameters and exceed customer expectations.

- Concast™ CSF 50 Crimped Steel Fiber

Concast CSF 50 is a low carbon, cold drawn steel wire fiber designed to provide concrete with temperature and shrinkage crack control, enhanced flexural reinforcement, improved shear strength and increase the crack resistance of concrete. It is a reliable, cost efficient concrete reinforcement that is designed to be easy to mix, place and finish. Concast CSF 50 Crimped Steel Fiber complies with ASTM C1116 and ASTM C1018, Standard Specification for Fiber Reinforced Concrete and Shotcrete and ASTM A820, Type I, Standard Specification for Steel Fibers for Fiber Reinforced Concrete.

Applications

- Industrial Floorings

- Ground slabs

- External Roads/ Pavements

- Composite Metal Decks

- Overlays

- Foundations

- Precast elements and structures

- Retaining walls

Advantages

- Improved crack control.

- Reduced slab costs.

- Reduced slab thickness.

- Reduced curling.

- Joint edges protected by steel profile.

- Improved ductile behavior.

- Reduced construction time.

- Simplified job site operation.

- No reinforcement placement mistakes.

- Eliminates handling of reinforcement.

- Generally no need of concrete pumping.

- Good impact resistance.

- Floor joint stability.

2. Concast™ ARG 12 Alkali Resistant Glass Fiber

Concast ARG 12 is an Alkali Resistant Glass (ARG) fiber used to reinforce cement and other alkali materials and to limit crack propagation in mortar & concrete. Concast ARG 12 is a high integrity strand to meet the requirements of conventional “premix” products. The chopped fibres disperse as strands in a matrix of mortar. The excellent strand integrity of Concast ARG 12 allows longer mixing time, and ensures uniform dispersion in the matrix and stable bending strength of GRC.

3. Concast™ NO CRACK 6/12 Fibrilliated Polypropylene Fiber

Synthetic fibers of modified polypropylene for use in fiber-reinforced concrete and mortars. Polypropylene fibers reduce the formation of plastic shrinkage cracks on concrete and increase the impact and shatter resistance. Synthetic fibers also increase abrasion resistance in concrete floors and reduce bleeding. Moreover, they improve the elasticity and cohesiveness of mortars and screeds during placing.

Concast™ CSF 50-Technical-Data-Sheet

Concast™ CSF 50-Technical-Data-Sheet Concast™ ARG 12-Technical-Data-Sheet

Concast™ ARG 12-Technical-Data-Sheet Concast™ NO CRACK 6/12-Technical-Data-Sheet

Concast™ NO CRACK 6/12-Technical-Data-Sheet