Surface Hardening

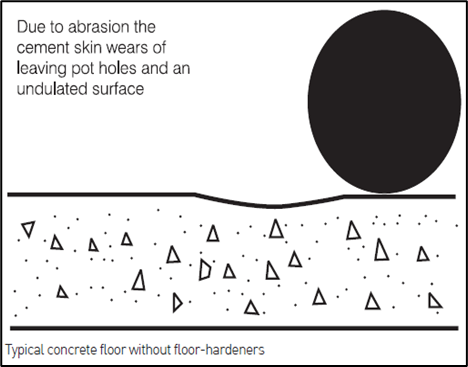

Many a time surface of a concrete floor is not hard enough for the type of use it is put to. The result is that it wears or dusts off rapidly. It is possible to increase the life of such floors by application of certain materials known as ‘hardeners’.

Floor hardeners are generally used for the purpose of hardening the upper matrix of Portland cement concrete surface, reducing the suction of liquids into the surface pores and preventing possible chemical attack. They are effective if the floor is of good quality, although they have sometimes been used successfully on inferior quality concrete surfaces too. Even on good quality concrete the treatment r.e ds renewal at intervals of one year or more depending on service conditions.

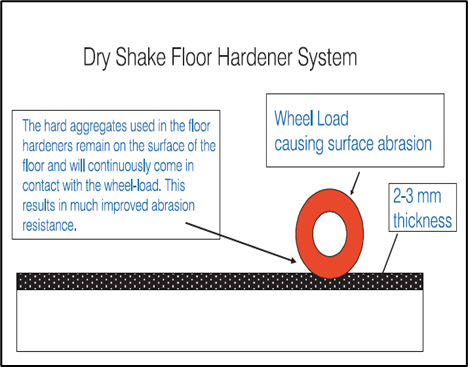

Floor-hardeners are a mixture of cement, aggregates (quartz, carborundum or iron particles) and other additives. They consume the rising water from the green concrete, hydrates and gives a hard-wearing and dense surface. The floors, thus cast have becomes an extremely durable, abrasion-resistant surface over a period of time and provides a fairly tough and wear-resistant surface.

Applications

- Industrial Floorings

- Ground slabs

- External Roads/ Pavements

- Parking Lots

- Ports

- Quays

Advantages

- High abrasion and impact resistance- Long service life

- Better abrasion resistance than plain concrete- Extended service life

- Non rusting- Suitable for wet environments

- Non-slip- Improved safety for personnel and forklifts in wet environments.

- Dense surface- Resists oil and grease penetration

- Coloured surface- Can create aesthetically pleasing environment

- Able to applied at higher ambient temperatures- Wide application range

Concast™ FH Non-metallic Dry Shake Floor Hardeners

Concast FH is a ready to use dry shake floor hardener composed of quartz-silica mixture of finely graded non-metallic aggregates, plasticizer and cement binder. It is an economical concrete floor hardener recommended for both interior and exterior use. The aggregates used have been selected for their shape, grading and high physical and mechanical quality.

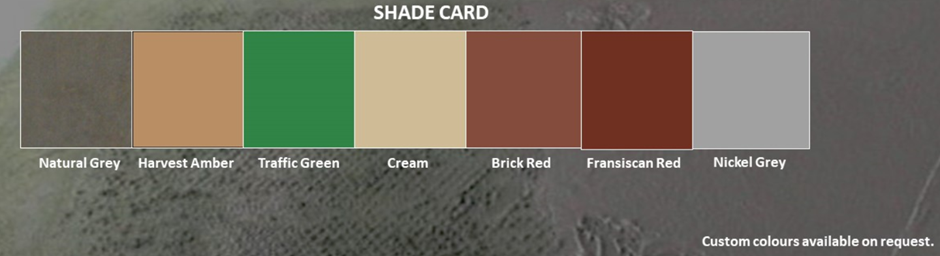

Concast FH is available in various shades for the purpose of coloured floors/ stamped concrete works depending on the requirements from various industries ranging from Hospital, Food & Beverages, Workshops, Manufacturing facilities, etc.

SHADE CARD

Applications

- Industrial Floorings

- Ground slabs

- External Roads/ Pavements

- Parking Lots

- Ports

- Quays

Advantages

- High abrasion and impact resistance- Long service life

- Better abrasion resistance than plain concrete- Extended service life

- Non rusting- Suitable for wet environments

- Non-slip- Improved safety for personnel and forklifts in wet environments.

- Dense surface- Resists oil and grease penetration

- Coloured surface- Can create aesthetically pleasing environment

- Able to applied at higher ambient temperatures- Wide application range