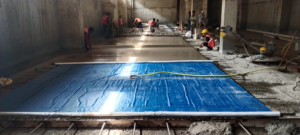

VD Flooring also known as Vacuum Dewatered Flooring is a special type of Flooring Technique to achieve High Strength, Longer Life, Better Finish and Faster Work. This type of floor is suitable for high abrasion & heavy traffic movement.

The Vacuum Dewatered Flooring or VDF Flooring is a system for laying high quality concrete floors where the key is Dewatering of Concrete by Vacuum Process wherein surplus water from the concrete is removed immediately after placing and vibration, thereby reducing the water: cement ratio to the optimum level. The vacuum dewatering results in coarse aggregate in the fresh mix being drawn to the top surface a further contributing factor in achieving wear-resistant concrete surfaces the surface of vacuum treated concrete is free of pitting, an important consideration for abrasion resistance and the possible exposure to a continuous flow of liquid over the member.

This type of floor is suitable for high abrasion & heavy traffic movement.

Advantage of Vacuum Dewatering System:-

- Increases the compressive strength by 40 – 70% (higher increase is at the top

surface). - Increases Wear Resistance.

- Reduces Shrinkage of Concrete

- Strength gain in Vacuum dewatered concrete is faster than the normal way, hence earlier usability is possible.

- Reduces porosity by 20% (i.e. Dense Concrete)

- 4-meter wide strip floor construction.